In 99.99% cases we laser cut one layer at the time. It is much easier to manage fabric on a laser cutting table and it is easier to control laser for clean cutting. Also, in many cases some fabrics will fuse to each other, due to the hot laser cutting that will melt and fuse fibers together.

Laser cut fabric

Laser cut lace

Laser cut fabric panels for the Art Basel Miami Show

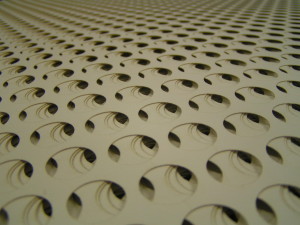

Laser cut material

Clean laser cut

Cost of files set up – $75/Hr. Very often – 1 Hr is enough time to prepare the files for cutting.

Cost of laser cutting textiles- $120/Hr

Minimum charges – $75 + $120 = $195 + shipping cost. This is a common charge for small runs and trials. The yield is less than in production, but gives an opportunity to conduct short trials.

We can cut large quantities and have number of companies that run their projects with us for years.

Cost of files set up – $75/Hr. Very often – 1 Hr is enough time to prepare the files for cutting.

Cost of laser cutting textiles- $120/Hr

Minimum charges – $75 + $120 = $195 + shipping cost. This is a common charge for small runs and trials. The yield is less than in production, but gives an opportunity to conduct short trials.

We can cut large quantities and have number of companies that run their projects with us for years.

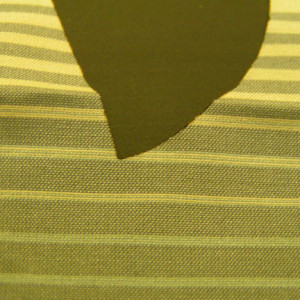

Fraying fabric

Laser cutting is very beneficial to prevent fraying.